Going Underground in Bisbee Arizona

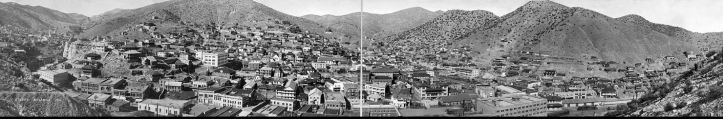

Bisbee was founded as a copper, gold, and silver mining town in 1880, and

named in honor of Judge DeWitt Bisbee, one of the financial backers of the

adjacent Copper Queen Mine. In 1929, the county seat was moved from

Tombstone to Bisbee, where it remains.

named in honor of Judge DeWitt Bisbee, one of the financial backers of the

adjacent Copper Queen Mine. In 1929, the county seat was moved from

Tombstone to Bisbee, where it remains.

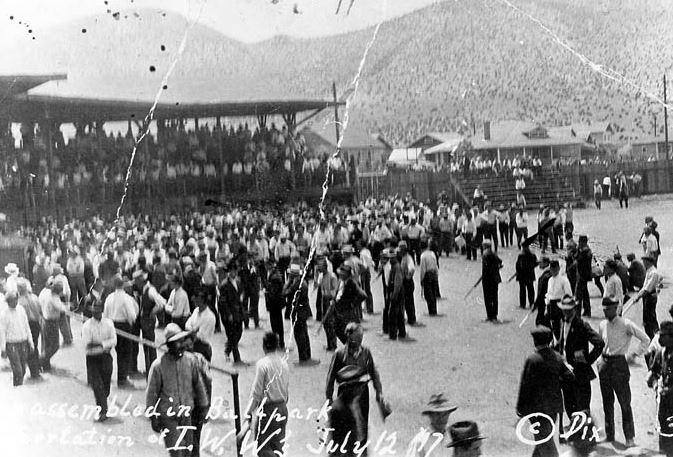

Greed was major motivator in town. As a result the Bisbee Deportation

took place. The workers lived and worked in deplorable conditions and

also small wages. Therefore the workers went on strike and as a result the deportation took place to prevent profit losses.

took place. The workers lived and worked in deplorable conditions and

also small wages. Therefore the workers went on strike and as a result the deportation took place to prevent profit losses.

The deportation was the the illegal kidnapping and deportation of about 1,300 striking mine workers, their supporters, and citizen bystanders by 2,000 members of a deputized posse, who arrested these people beginning on

July 12, 1917. The action was orchestrated by Phelps Dodge, the major mining company in the area, which provided lists of workers and others who were

to be arrested in Bisbee, Arizona, to the Cochise County sheriff,

Harry C. Wheeler.

July 12, 1917. The action was orchestrated by Phelps Dodge, the major mining company in the area, which provided lists of workers and others who were

to be arrested in Bisbee, Arizona, to the Cochise County sheriff,

Harry C. Wheeler.

These workers were arrested and held at a local baseball park before

being loaded onto cattle cars and deported 200 miles (320 km) to Tres Hermanas in New Mexico. The 16-hour journey was through desert without

food and with little water. Once unloaded, the deportees, most without

money or transportation, were warned sternly against returning to Bisbee.

being loaded onto cattle cars and deported 200 miles (320 km) to Tres Hermanas in New Mexico. The 16-hour journey was through desert without

food and with little water. Once unloaded, the deportees, most without

money or transportation, were warned sternly against returning to Bisbee.

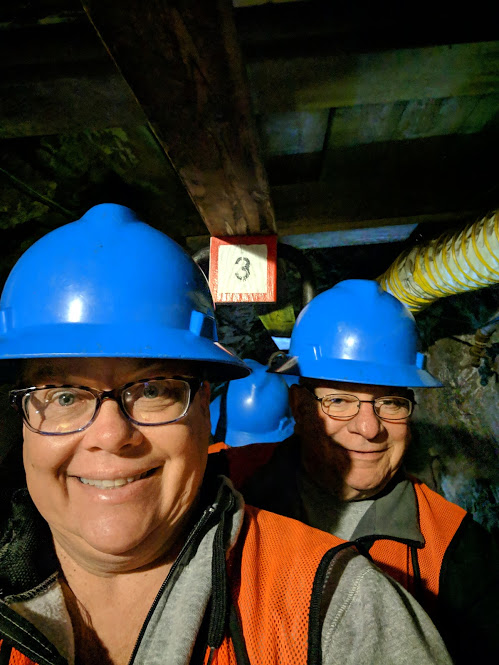

Martha and I visited Bisbee and took a tour of the Copper Queen Mine, a

hard rock mine in Bisbee that is played out and is now a tourist attraction.

hard rock mine in Bisbee that is played out and is now a tourist attraction.

Outfitted in hard hat, miner’s headlamp, thousands of Bisbee visitors ride into the Queen Mine Tour each year—heading underground and back in time. Tour guides, retired Phelps Dodge employees, lead the groups 1,500 feet into

the mine and recount mining days, techniques, dangers and drama. Adding a personal touch, the miner-turned-tour guides help visitors experience what

it was like to work underground. Tours depart each day, seven days a week,

from the Queen Mine Tour Building, located immediately south of Old Bisbee’s business district, off the U.S. 80 interchange.

the mine and recount mining days, techniques, dangers and drama. Adding a personal touch, the miner-turned-tour guides help visitors experience what

it was like to work underground. Tours depart each day, seven days a week,

from the Queen Mine Tour Building, located immediately south of Old Bisbee’s business district, off the U.S. 80 interchange.

The town is an interesting place though we didn’t see as much of it as we

wanted. Instead we did the mine tour and then went to a local micro-brewery.

wanted. Instead we did the mine tour and then went to a local micro-brewery.

After donning our safety equipment we were ushered onto the mine train.

This is the original train that ferried workers underground and back to the

surface. It’s very narrow and you sit facing forward while straddling a seat

somewhat like sitting on a horse saddle.

This is the original train that ferried workers underground and back to the

surface. It’s very narrow and you sit facing forward while straddling a seat

somewhat like sitting on a horse saddle.

Mining in Bisbee wasn’t limited to hard rock mining. It also included

strip mining and where possible hydraulic mining.

strip mining and where possible hydraulic mining.

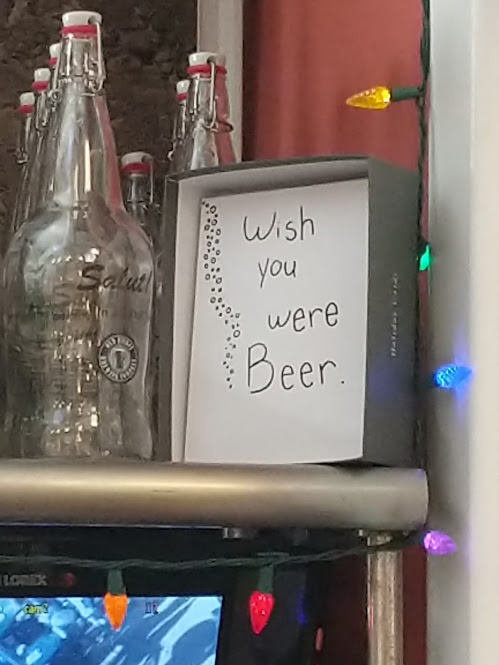

After the mining tours we made our way to the “Old Bisbee Brewery”

This spot is a local’s favorite and turned out to have great beer.

This spot is a local’s favorite and turned out to have great beer.

I can recommend the mine tour and the Brewery. It was very interesting to

learn the techniques used to extract the ores. The Copper Queen produced

some the most pure copper ore ever found it averaged 25% in purity.

learn the techniques used to extract the ores. The Copper Queen produced

some the most pure copper ore ever found it averaged 25% in purity.